SMC-NCT-02 Two Axis Punching CNC Controller

Feature:

1. Support X Y 2 axis motion;

2. Easy to learn, friendly interface, convenient operation;

3. Can preview process track and real-time following;

4. Support twice relocation and clamp avoid function, realize palte no dead zone process;

5. With single punch, continuous punch, step punch etc. different kinds of punching mode, increase the process efficency;

6. Can recognize CAD convert code, compatible with usual punching machine software code, support CAM template programming;

7. With complete self-diagnostic function, internal and external real-time display, it will show alarm if any exception;

Optional Spare Parts:

(Handheld box-CNC4A)

(Handheld box-CNC4A)  (Additional panel- FCNC4M)

(Additional panel- FCNC4M)

Function:

1. X, Y two axis micron level interpolation accuracy controlling;

2. USB/U dis/RS232COM etc many kinds of communication mode, to help users achieve different data transmission and software upgrades easily;

3. Macro variable, macro definition programming,realizing a variety of logical relations. Support macro program with parameters, convenient to the user programming;

4. CAD graphics automatic conversion processing program, CAM graphics library function, include a variety of commonly used graphics;

5. According to the program code automatically generated processing locus, real-time tracking processing position when processing;

6. Breakpoint memory function, can choose from the breakpoint to continue processing under program abnormal circumstances;

7. Two aixs system match with manual die change of punching machine, system will pause and remind to change die when there is die changing instruction in the procedure;

8. Single-punch, continuous,single-stage of a variety of processing methods, oplate automatic relocation, clamp protection zone function;

9. The highest fast moving speed reach 60 M/min, the highing feed speed reach 30M/min;

10. Servo AB encoder closed-loop control to ensure feeding accuracy;

11. Support secondary relocation and clamp giving way function, come true board without dead zone processing;

12. Fully compatible with procam CAM software and addition punching machine special compound instruction;

13. CAM wizard type punching instruction programming, can directly start punching processing program after filling in hole location information;

14. DXF + G code templates graphics analysis, can convert CAD files to processing files directly, no need softdog supporting;

15. Support powerful class B macro analysis function, convenient for users to develop their own motion control program;

16. Dead point detection, clamps loosen alarmimg, main motor doesn’t open alarming etc richful protection functions.

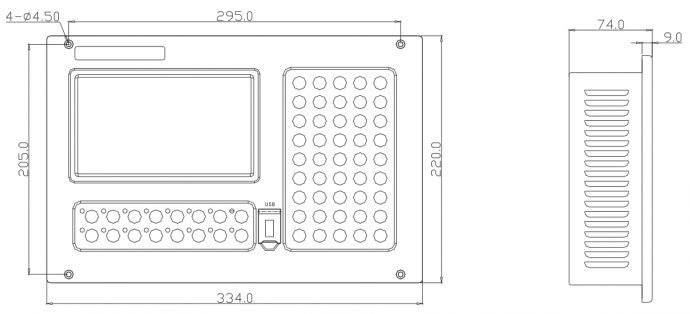

Size: