SMC-8949G1 High-end PCI Bus 4-axis Motion Control Card

Overview:

Summary: SMC-8949G1 motion control card is the four axis based on high performance computer PCI bus motion control card, a member of a system can support up to 10 pieces of control card, servo/ step motor can control 40 road. T, S, C and E a variety of deceleration, point and trajectory planning function, also have electronic gear, electronic CAM synchronous motion planning function, linear interpolation, arc interpolation programming function, spline curve, follow, and other functions. Especially suitable for high speed, high precision accurate position control requirements of the occasion. The products are widely used in testing, semiconductor packaging, mechanical arm, point glue, packing, sculpture, PCB processing industries. Movement control CARDS - PCI bus. High performance four axis servo, stepper control card.

Hardware Index:

1. Hardware indicators;

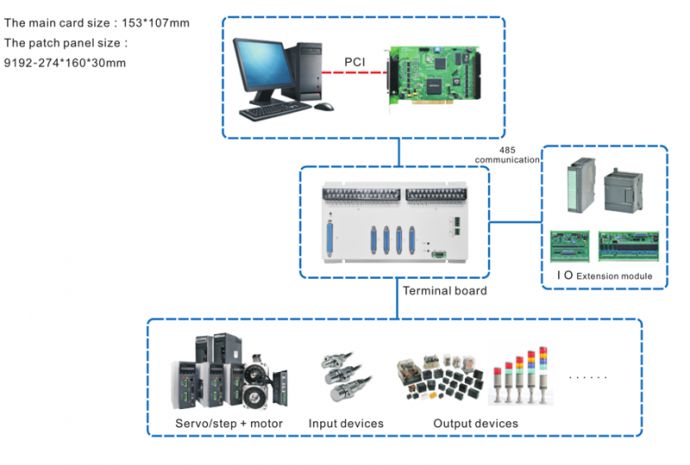

2. The 32 bit PCI bus, plug and play;

3. Can control shaft number: four axis;

4. Maximum 5 MHZ pulse output frequency;

5. Each shaft encoder feedback channel A/B or phase difference between the pulse input and pulse input, the 32-bit count, frequency up to 2 MHZ, 4 ratio;

6. Pulse output type: pulse direction + + DIR (PUL) or double pulse (the CW and CCW);

7. Large capacity of multi-axis cache interpolation function, can store 10000 interpolation instruction;

8. 2 road, DA output, range of 0 to 10V;

9. 1 road 485 communication interface;

10. Support hardware serial number, but a third party hardware encryption.

Control function:

1. Any 2-4 axis hardware linear interpolation, 2-3 axis hardware arc interpolation;

2. Forward speed, continuous interpolation function;

3. Spline interpolation function;

4. Gantry double drive control function;

5. An external signal trigger multi-axis position latch;

6. Movement of the real-time change speed and target position;

7. Hardware stop function, multi-axis with moving with stop;

8. The cache increases the output control functions;

9. Multiple processes and control function;

10. A variety of ways to zero;

11. Signal filter.

Software support:

1. Operating system: DOS/WINDOWS95/98/NT/2000XP/WINCE, WIN7;

2. Programming environments: C/BC++/VC/VB/C#/C++Builder/Delphi/LabVIEW/EVC;

3. Application examples of open-DOS and Windows.

Application environment:

1. Operating temperature: 0-60℃;

2. Storage temperature: -20-80℃;

3. Temperature: 5-95% non-condensing.

Dedicated purpose IO:

1. Mechanical or limit, the origin;

2. Position latch input signal;

3. The handwheel control signal;

4. Hardware stop signal;

5. Alarm input signal;

6. Alarm clear signal;

7. Servo enabled signal.

General purpose IO:

1. Special signals need not when can be set to general IO, most can be achieved;

2. General purpose digital input, 36 road all optical coupling isolation;

3. 32 open collector output;

4. Can be extended through 485 communication interface and general IO module.

Wiring diagram:

Application industries:

1. Machine vision and automatic detection equipment;

2. Biology, medicine automatic sampling device;

3. Cutting equipment: diamond cutting machine, sponge cutting machine;

4. Motor processing industry: dispensing;

5. Semiconductor packaging industry: solid crystal machine;

6. Industry: CNC machine;

7. Packaging and printing equipment, printing machine, pad printing machine;

8. Engraving equipment;

9. Industrial robot equipment;

10. PCB processing and other industries.