DAP03 AC Spindle Servo Drive

Introduction:

Wide timing range, small speed fluctuation and short starting/braking time, DAP

Characteristics:

1. High performance DSP and CPLC to realize digital control and high reliability;

2. High pressure AC busbar(600V), big power IPM, excellent dynamic response;

3. Asynchronous motor vector control, wide valid timing range and small speed fluctuation;

4. External contact signal can the spindle orientation and set 8 positioning points;

5. Three-phase 380V direct input without power transformer to get the convenient installation and low cost.

Technical specifications:

Drive unit type | DAP03-037 | DAP03-055 | DAP03-075 | DAP03-110 | |

Continuous output power (S1) | 3.7kW | 5.5kW | 7.5kW | 11kW | |

30min output power (S2) | 5.5kW | 7.5kW | 11kW | 15kW | |

Input power supply | 3 three-phase AC380V(-15%~+10%) 50/60Hz | ||||

Working mode | Internal speed run, external speed run, Jog, trial run, position run, speed/position switch run | ||||

Constant torque timing ratio | 1000:1(corresponding motor speed 1.5~1500 r/min) | ||||

Constant power timing ratio | 4:1(corresponding motor speed 1500~6000r/min) | ||||

Stead speed precision | Foundation speed(rated speed)×0.1% | ||||

Speed control mode | Speed closed loop control with speed feedback | ||||

External speed command input | -10V~+10V or 0~+10V | ||||

Speed feedback input | Incremental rotation encoder signal feedback, lines 128~8000p/r,A/B/Z differential signal | ||||

Position run mode | Input mode | ①pulse+direction ②CCW pulse/CW pulse ③A/B two phases orthogonal pulse | |||

Electronic gear ratio | gear ratio numerator 1~32767 gear ratio denominator 1~32767 | ||||

Orientation function | Set 8 orientation points on the motor encoder or the spindle encoder, the external contact selects the orientation point, start motor(spindle) orientation, orientation angle deviation≤ | ||||

Spindle position feedback input | Incremental rotary encoder signal fee, lines 128~8000p/r,A/B/Z differential signal | ||||

Position feedback output | Motor encoder or spindle encoder signal 1:1 output, A/B/Z differential signal | ||||

Control input signal | 7 input interfaces: servo enabling, zero speed clamp, CCW, CW, speed(orientation point), orientation start, speed/position switch and so on | ||||

Control output signal | 7 output interfaces: alarm, ready, speed arrival, orientation completion, zero speed output, speed/position switch, motor Z pulse | ||||

Protection function | Protection from overvoltage, undervoltage, overspeed, overcurrent, overload, overheat, abnormal encoder and so on. | ||||

Display function | 6-bit LED,displaying software/hardware version, working mode, current speed, speed command, encoder position/state, current, torque, I/O state, busbar voltage, alarm code, parameter and so on | ||||

Operation function | 5 pressing keys to select working mode and display content to modify parameters and so on . | ||||

External brake resistance | Refer to Brake Resistance Allocation Table | ||||

Storage temperature and humidity | Below -40~55℃ / 95%RH(40℃) | ||||

Working temperature/humidity | 0~40℃ / 30%~95%(no dewing ) | ||||

Vibration | ≤0.6G(5.9m/s2) | ||||

Protection grade | IP20 | ||||

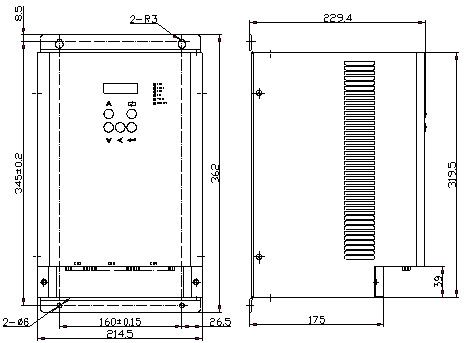

Appearance dimension | 214.5×362×229mm | ||||

Note 1: The servo motor with the special polar and the basic frequency is specially ordered, and the optional servo unit must use the exclusive software; max. speed of the standard allocation servo motor is 6000r/min, and the motor with more 6000r/min speed is ordered specially;

Note 2: When the ratio between the servo motor and the spindle is 1:1 without gap drive, the spindle can complete the exact orientation without the spindle encoder; when the ratio is not 1:1, the spindle cannot does without the spindle encoder.

Appearance Dimension: