Products

-

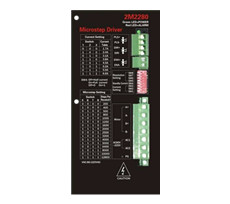

The 2M2280 is one of the few Direct-On-Line Step Motor Drive, available in the industry, which can be simply power up from the AC power source without the need of a Power Supply. This makes it cost effective and space.

Arc Welding Robots

Arc Welding Robots utilize the intense heat needed to melt metal, which is produced by an electric arc. The arc is formed between the actual part and an electrode (stick or wire) that is manually or mechanically guided along the joint. The electrode can either be a rod with the purpose of carrying the current between the tip and the work or a specifically prepared rod or wire that not only conducts the current but also melts and supplies filler metal to the joint. The latter is typically used with steel product manufacturing.

Robotic arc welding is one of several fusion processes for joining metals. Arc welding robots apply intense heat to metal at a joint between two parts so that the parts melt and intermix. This is either done directly, or more commonly, with an intermediate molten filler metal. Since the joining is an intermixture of metals, the final weldment potentially has the same strength properties as the metal of the parts. Because of this intermixture of metals, arc welding is quite different from non-fusion processes of joining in which the mechanical and physical properties of the base materials cannot be duplicated at the joint. An arc welding robot is the most common robotic welding application. Please refer to any available welding robot below to find out more detailed information on which robot is most suitable for your application.

SAMCO is a full-service arc welding robot integrator. We offer customized arc welding robot solutions and robot welding equipment for a variety of industrial projects. SAMCO is committed to constructing the best system to meet every customer need. We provide training, extensive warranties and support with every robot package deal.